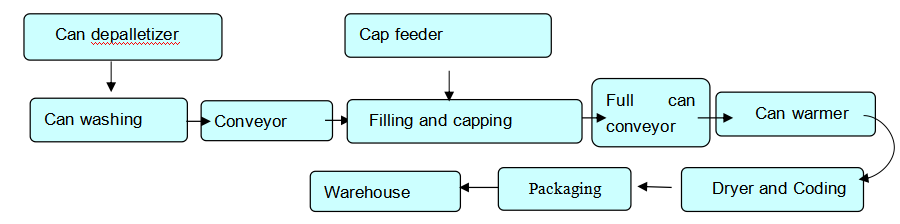

Kudzaza System

Aluminium Can Carbonated Water filler & phukusi

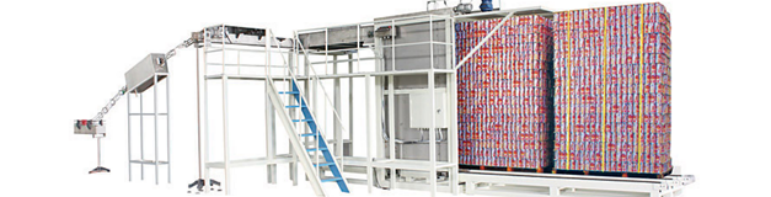

A) Zitini zopanda kanthu depalletizer

Pop can empty can depalletizer ndiye makamaka oyenera depalletizing athunthu milu ya zitini opanda kanthu. Imakwezera zitini zopanda kanthu zopakidwa pallets wosanjikiza kuchokera pansi kupita pamwamba ndiyeno kupita ku mbale yotumizira unyolo. Ikagwiritsidwa ntchito limodzi ndi chochapira chopanda kanthu, imatha kulowa m'malo mwa njira zamakonzedwe ndi makina otsitsa opanda kanthu, kupulumutsa antchito ambiri ndikuwonjezera zotsatira zopanga.

Panthawi yogwira ntchito, forklift imayika ma pallets pomwe zitini zopanda kanthu zimayikidwa pa pallet conveyor, ndipo woyendetsa amawatengera ku nsanja yokweza mphasa yamakina akulu. Pulatifomu yonyamulira pallet imagwiritsidwa ntchito kutumiza zitini zopanda kanthu zomwe zili pamtunda wotsitsa. Pamene zitini zopanda kanthu zatsitsidwa, mapaleti opanda kanthu amagwa ndikuyikidwa pa conveyor. Zochita zonse zokwera ndi kugwa zimayendetsedwa ndi chipangizo chodzitsekera chokha. Liwiro lokwera kapena lotsika litha kusinthidwa padera kuti likwaniritse zosowa za opareshoni. Pakutsitsa kopanda kanthu, galimotoyo imayendetsa gudumu la unyolo ndi chipangizo cha unyolo kukankhira zitini, ndiyeno milu yonse ya chitini chopanda kanthu idzakankhidwira pa chotengera cha ukonde, ndikubwerera kumalo okonzekera ndikupitiriza kukankhira kunja. mulu wotsatira. Kuyika kulikonse kumayendetsedwa ndi chosinthira cha photoelectric. The akhoza kutsitsa ndi zochita mosalekeza kapena single kuzungulira mode akhoza kusankhidwa.

Njira yodyetsera pallet, imatha kutulutsa mayendedwe ndi malo ogwirira ntchito pamakina amatha kusinthidwa mosavuta malinga ndi zomwe wogwiritsa ntchito amafuna.

Main technical parameters:

Mphamvu yopanga: 30 ~ 400can pa mphindi

Mphamvu: 3.5kw

Kulemera kwake: 2500kg

kukula: 7000*4500*3500mm

B) Slideway imatha kutsuka

Kutsogolo chitha kutembenuza khola locheka la washer limalumikizidwa ndi mayendedwe othamanga a chitoliro chotsegulira tebulo. Zitini zopanda kanthu zomwe zimachokera ku makina otembenuza zitini zimakhala ndi 180 ° kutembenuka. Ndiye chitini cholowa mu thanki yochapira yopanda kanthu chikhoza kutsuka potsegula kunsi. Kumbuyo kwa thanki ndi gawo la drainage. Madzi, omwe amawathira mu chopanda kanthu amatha kuyenda kumbuyo kwa thanki, ndiye madzi otayira otulutsidwa ndi mapaipi otulutsa. Pambuyo poyeretsa chopanda kanthu kumatha kukhala ndi 180 ° kutembenukira kumbuyo kwa makina otembenuza, ndiye amatha kulowa lamba wonyamula chakudya potsegula m'mwamba.

Main technical parameters:

Mphamvu yopanga: 30 ~ 400can pa mphindi

Kulemera kwake: 150kg

kukula: 4000 * 500 * 2300mm

C) Mutha Filler / Sealer

The monoblock imapangidwa:

FILLER-SEALER

Mau Oyamba:

Ndikoyenera kudzaza ndi kutsekemera zakumwa za carbonated monga cola, carbonated water etc. Ili ndi chipangizo chapamwamba, zipangizo zamagetsi, ndi teknoloji yolamulira pneumatic. Imakhala ndi mawonekedwe odzaza mokhazikika, kuthamanga kwambiri, kuwongolera kwamadzimadzi, kuwongolera modalirika, nthawi yosinthira pafupipafupi, kutaya zinthu zochepa. Itha kukhala ndi dongosolo lowongolera mtunda wautali. Ndi zida zomwe amakonda kwambiri popangira mowa wapakatikati ndi chakumwa.

Zofunika Kwambiri:

* Nyumba yamasiye yosindikizidwa kwathunthu yomwe ili yokongola, yachidule, yosavuta komanso yogwiritsidwa ntchito kwambiri;

* Kapangidwe ka thanki yoyendetsa njinga ndi kupukuta mwatsatanetsatane mkati;

* Ma valve olondola kwambiri komanso othamanga kwambiri kuti akwaniritse zofunikira;

* Mapangidwe odzigudubuza opangidwa mwapadera omwe ndi osavuta kusinthidwa, kutsekedwa ndikuwonetsetsa kuti ntchito yosindikiza;

* Gulu lothandizira komanso losavuta kugwiritsa ntchito komanso kufalikira kwakukulu.

* Valavu yodzaza imatenga valavu yolondola kwambiri, kudzaza mwachangu, mulingo wamadzimadzi kwambiri.

* Vat yodzaza imatenga 304L zida zopangidwa ndi chitsulo chosindikizira, kuti zikwaniritse kudzaza kokakamiza.

* Kuthamanga kwa valve yodzaza> 125ml/s.

* Kutumiza kwakukulu kumatengera lamba wokhala ndi mano ndi ma gearbox otsegulira amtundu wotseguka, kuchita bwino kwambiri, phokoso lochepa.

* Kuyendetsa kwakukulu kumatengera kusintha kwapang'onopang'ono kwa kutembenuka pafupipafupi, makina onse amatengera kuwongolera kwa PLC; makina ojambulira ndi makina odzazitsa amatengera kuphatikizana, kuti awonetsetse kulumikizana kwa makina awiri.

* Ndi kudzaza ndi chitini, palibe kudzaza popanda chitini.

* Njira yodzaza ndikudzaza kukanikiza kosalekeza, ndi liwiro lodzaza komanso kuchitapo kanthu kokhazikika.

* Kutengera ukadaulo wathunthu waukadaulo waku Switzerland (Ferrum).

* Capping trolley imagwiritsa ntchito chitsulo cholimba kwambiri (HRC>62), capping curve imagwiritsa ntchito makina opukutira mwatsatanetsatane, kuti zitsimikizire mtundu wa capping.

* Ndi capping with can, no capping without can control system, kuonetsetsa kuti makinawo aziyenda bwino.

* Ndi CIP automatic rinsing ntchito.

* Ndi centralized lubrication system.

Kachitidwe Kantchito:

Zitha kukankhidwira mu chitini chogwirizira nsanja imodzi ndi imodzi mwa kudyetsa screw ndi star-wheel. Chikho chapakati cha valavu yodzaza chidzagwa mpaka chitini; mtunda pakati pa ma valve odzaza ndi zitini umasindikizidwa ndi mphete ya pulasitiki ya springiness. Kusuntha kwa kapu yapakati kumapangidwa ndi gudumu la pulasitiki losagwira ntchito limodzi ndi curvilinear motion. Pambuyo kudzazidwa, valavu idzatsekedwa, mpweya umatulutsidwa, ndipo chikho chapakati chidzakwera kuchokera pachitini. Chikho chodzaza chidzatumizidwa ku unyolo wa conveyor, kenako ku capper. Capper atenga kapu, kutembenuza m'mphepete mwa chitini ndikutembenuza m'mphepete kuti amalize kusindikiza ndikuwongolera kwa cam. Pambuyo pake, zitha kusamutsidwa ku dongosolo lotumizira.

Zofotokozera Zazikulu:

1. Zida za valve yodzaza: Chitsulo chosapanga dzimbiri SUS304

2. Zida za tray yozungulira ndi nsanja ya makina: Chitsulo chosapanga dzimbiri SUS304.

D) Makina ofunda

Makina osalekeza osalekeza awa adapangidwa kumene ndikupangidwa poyambitsa njira zapamwamba zakunja. Amagwiritsidwa ntchito poyezera zakudya, monga madzi a mabotolo apulasitiki/magalasi ndi mowa, malata ndi aluminiyamu amatha kuthira madzi mopanikizika wamba, komanso kuziziritsa tiyi wotentha ndi zakumwa zamadzimadzi ndikuwotha kutentha pang'ono kudzaza carbonated-soft. zakumwa.

Makinawa amaphatikizidwa ndi kupopera madzi otentha mozungulira, madzi ofunda asanayambe kuziziritsa, ndi zigawo za zitini zotenthetsera zomwe zimatha kupeza madzi abwino komanso kuteteza mphamvu. Zitini zonse zizichitidwa ndikuzitulutsa zokha, ndipo mzerewo ukhoza kukwaniritsidwa wokha. Thupi lonse la makinawo limapangidwa ndi zitsulo zosapanga dzimbiri 304; Kuphatikiza apo, makinawo ali ndi mawonekedwe abwino, oyenda bwino komanso osavuta kugwira ntchito.

E) PE Film Shrink-wrapping Machine

Mapulogalamu:

1. Chitsanzo: LYBS6545auto film kukulunga makina

LYBS 6545 makina opangira mafilimu amapangidwa ndikupangidwa kutengera ukadaulo waposachedwa, chifukwa chofuna kulongedza zofunikira pakupanga chakumwa, monga madzi oyera, madzi amchere, madzi, zakumwa zozizilitsa kukhosi, ndi zina. Ndiwokutira basi, wokhala ndi ngalande yocheperako, yodzaza bwino.

2. Mawonekedwe a makina a LYBS 6545 auto film wrapping

1) Makina ojambulira otengera okha, omwe ali ndi chowongolera cholekanitsa chitsulo chosapanga dzimbiri ndi mbale yosanja yomwe imapanga mabotolo mu mpukutu wokhazikika kuti azitha kukulunga, kuonetsetsa kuti gulu la mabotolo a 3 x 4, 4 x 6, kapena 2 x 6, 4 x 5 ma PC a mabotolo m'malo ofunikira kukulunga.

2) Makina opangira ma membrane a PE, omwe amakhala ndi makina apamwamba komanso otsika a PE omwe ali m'malo mwake ndipo amakhala ndi makina ozindikira a infra-red poyang'ana gulu la mabotolo omwe akukonzekera kukulunga ndi kudula, njira yonseyi ndi zichitike nthawi yomweyo ndi PLC control system.

Mabotolo okulungidwawo amakankhidwira mumsewu womwe ukucheperachepera ndi makina okankhira okha, omwe amakankhira botolo lokulungidwa pa chotengera cha ngalandeyo yomwe ikucheperachepera.

3) Mphepo yowotcha yokhayokha, njira yocheperako ndi gawo lopatukana la makinawo lomwe lili ndi gawo lopatukana lowongolera kutentha komwe kumayendetsedwa ndi makina owongolera kutentha.

4) Kukhudza screen control panel ndi PLC ndi magetsi dongosolo ulamuliro.

F) Makina odzaza mabotolo a Conveyor

Zofunikira zazikulu:

1. Kutumiza kokhazikika, pogwiritsa ntchito njira yothamangitsira pakati pa lamba wotumizira ndi injini, kupanga mabotolo kukhala abwino potumiza: osagwa, osatsekeka, osapanikizana. Ndipo nsanja ya cushion ikhoza kukhazikitsidwa musanalembe makina, chizindikirocho chikasinthidwa, makina odzaza amatha kugwira ntchito, osafunikira kuyimitsa ndikudikirira. Zomwe zimadzazidwa panthawiyi zimasungidwa ndi khushoni, kusintha zilembo zikamalizidwa, makina olembera amalemba zomwe zasungidwazo mwachangu kwambiri, ndikutulutsanso liwiro.

2. Lamba wotumizira amapangidwa ndi module, chigawocho chikhoza kusinthidwa mosavuta, kapangidwe kake kamakhala kakang'ono, phokoso ndi laling'ono, kusonkhanitsa kosavuta ndi kusunga, kukhala ndi kusinthasintha kuphatikiza mtundu wa botolo molingana ndi mphamvu zosiyana.

3. Mapangidwe a kayendetsedwe ka magetsi ndi apamwamba komanso omveka, tikhoza kupanga njira yoyendetsera, kusankha chigawo chowongolera magetsi malinga ndi dongosolo la kasitomala, kuti tipititse patsogolo kukhazikika kwa kutumiza.

4. Sinthani molingana ndi kutumiza masanjidwe kachitidwe kapena kasitomala wololera zofunikira, kuti zitheke kugwira ntchito.

5. Lamba wothira mafuta ali ndi zida.

6. Gawo lalikulu lonse pogwiritsa ntchito SUS304.

7. Fringe board ikugwiritsa ntchito ukadaulo wa US Rexnord kupanga.

Nthawi yotumiza: Nov-30-2022